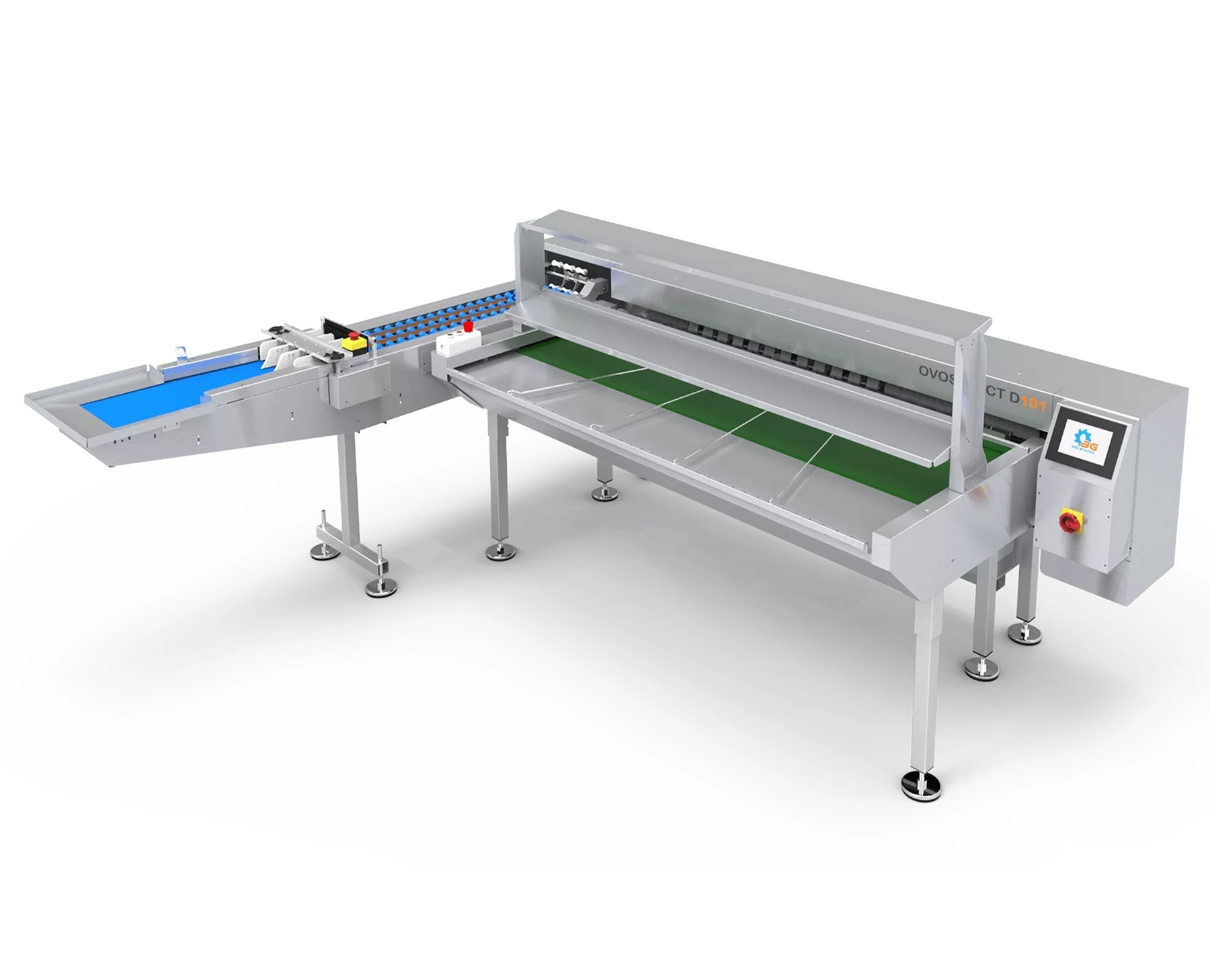

OvoSelect DX300 – Fully Automatic Egg Grading and Packaging System

Brochure Download Brochure

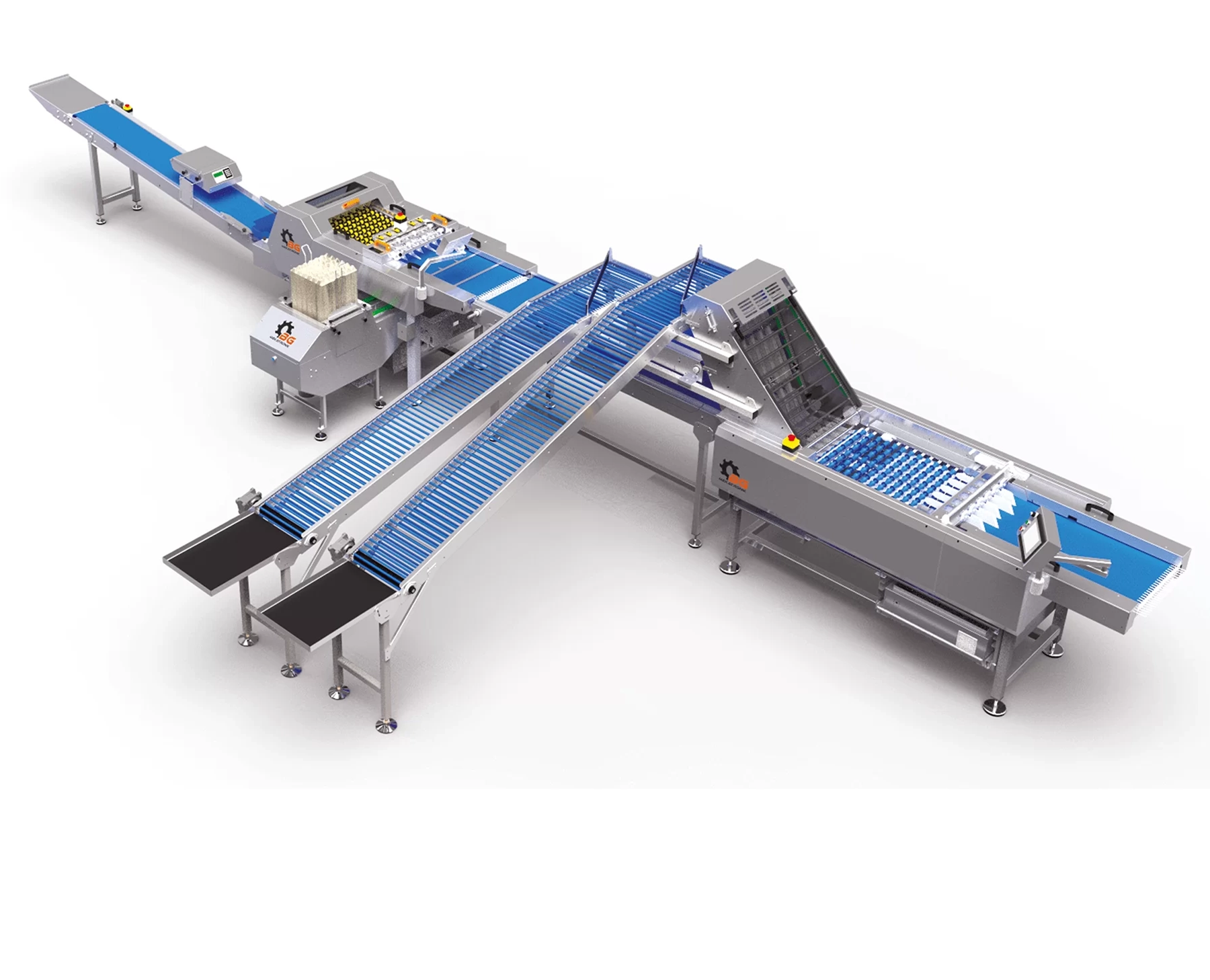

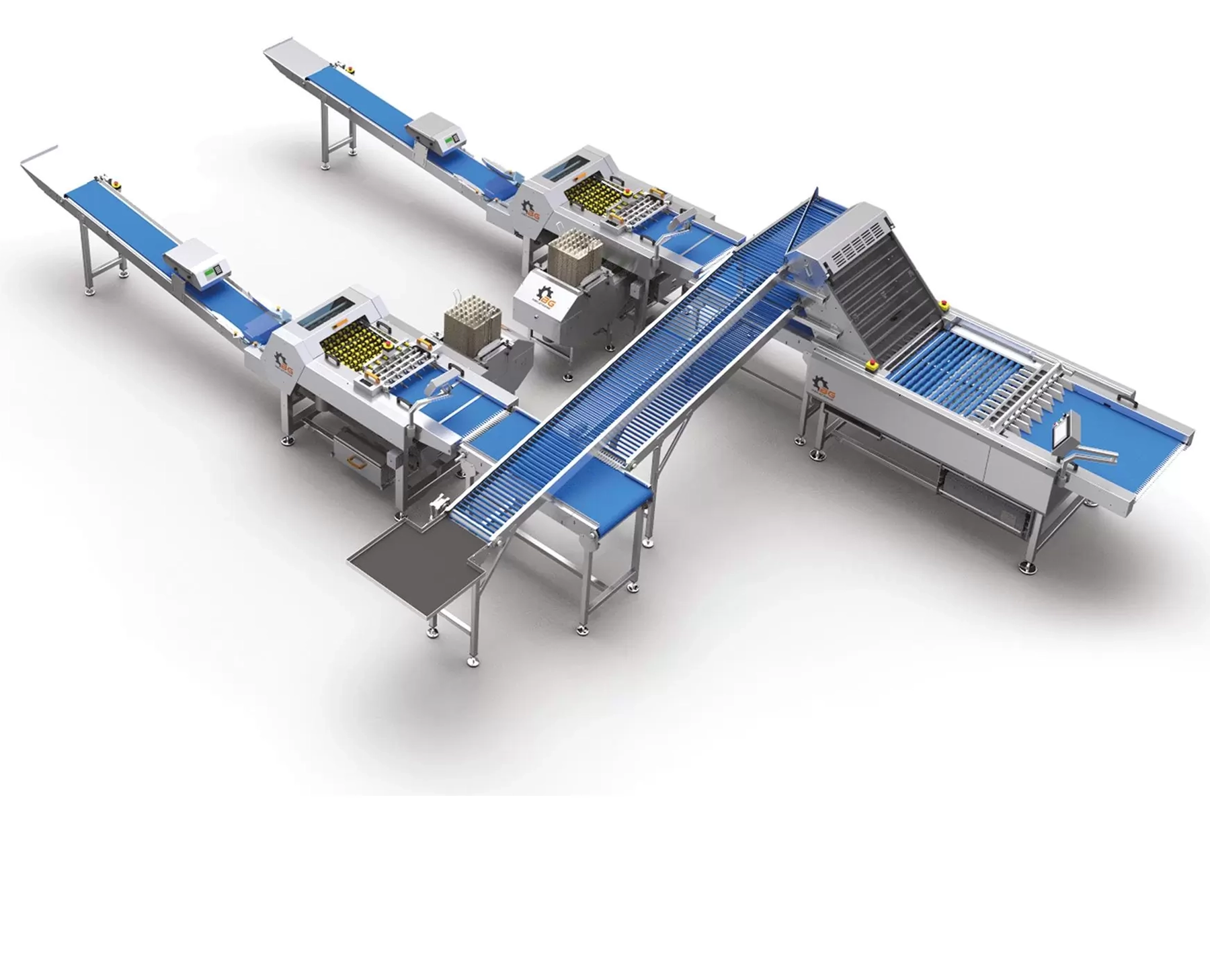

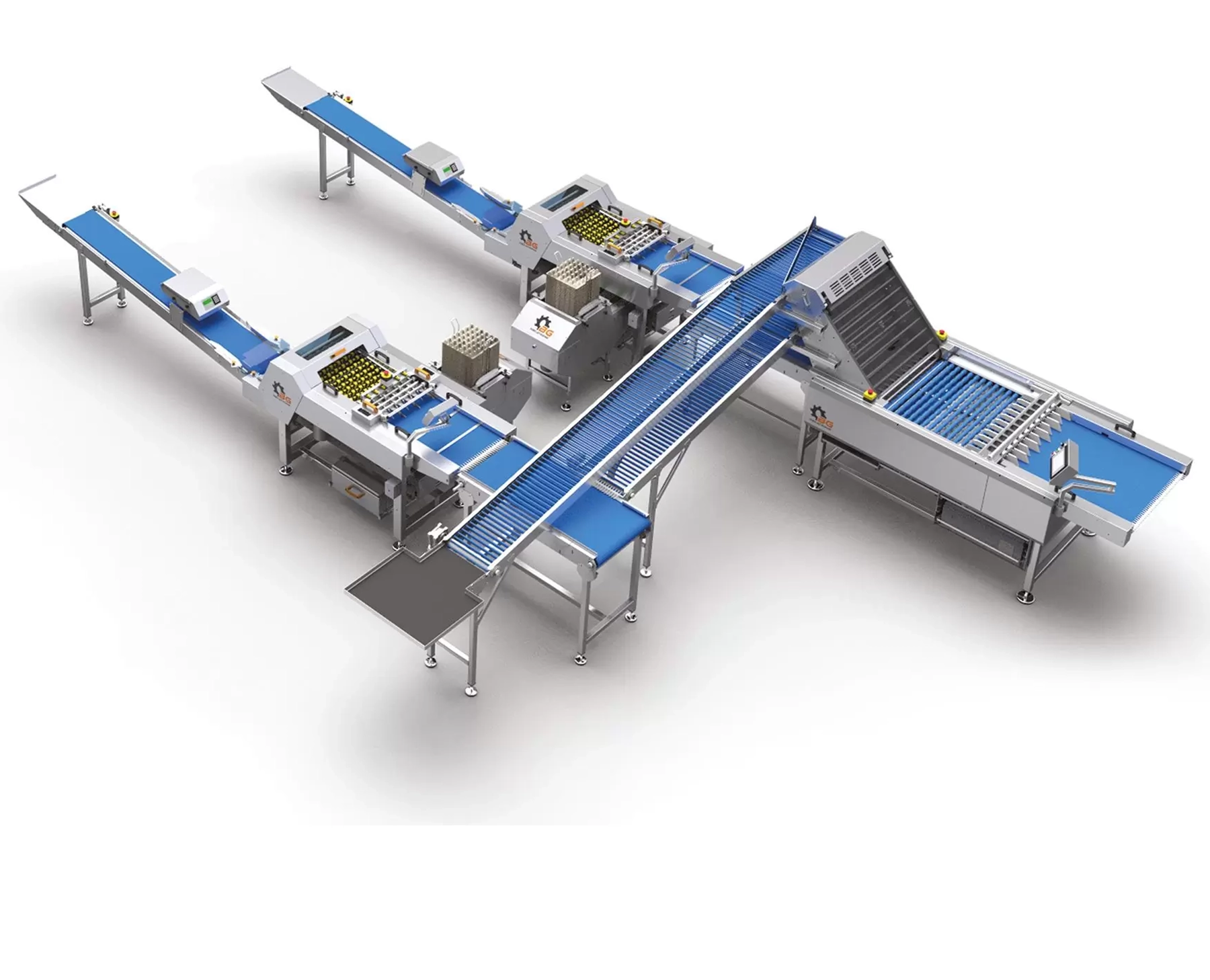

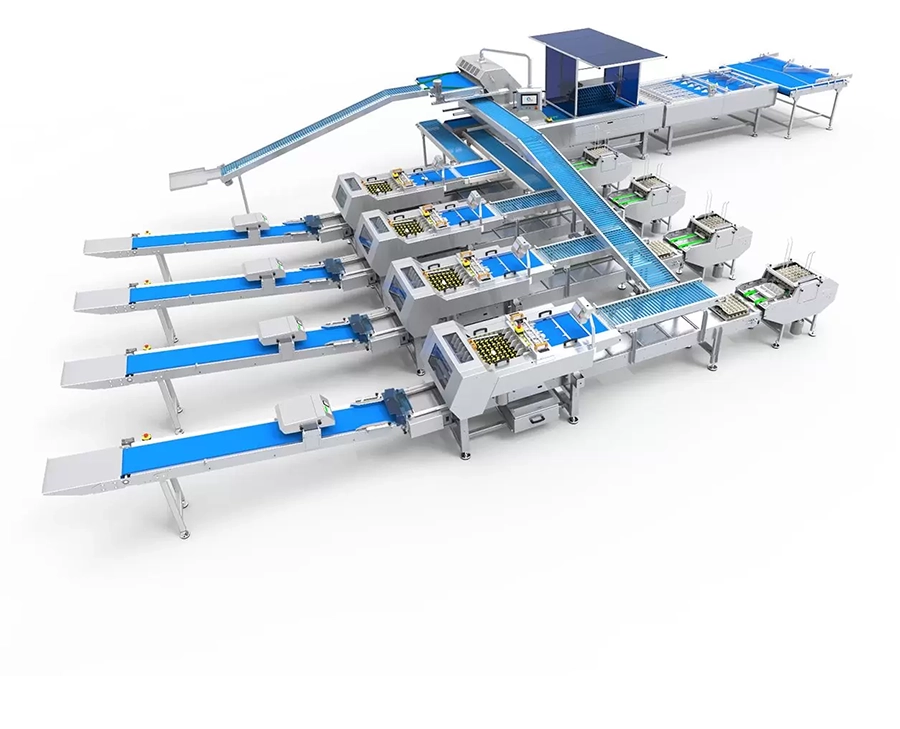

OvoSelect DX300 is a new medium-capacity fully automatic egg grading and packaging system.

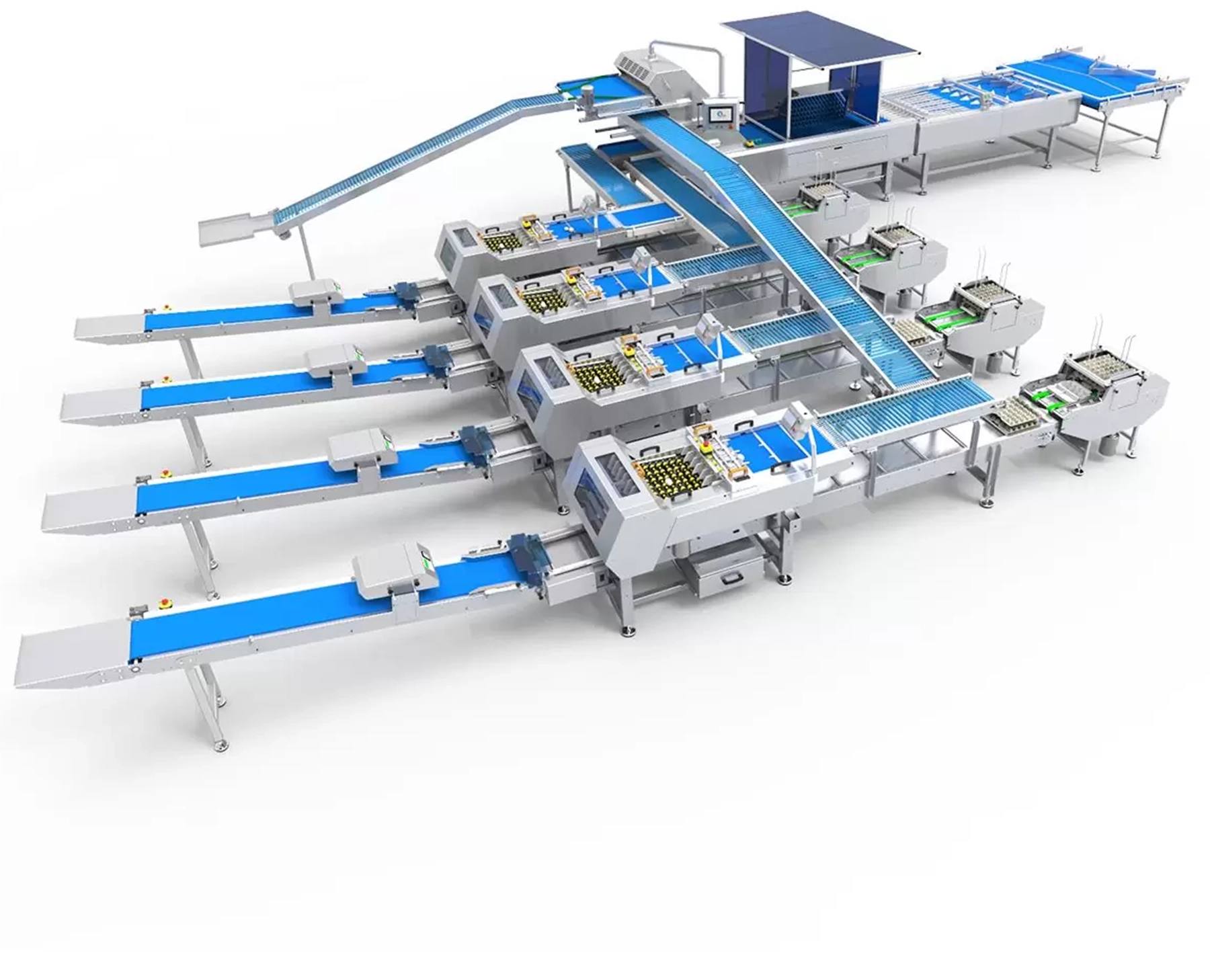

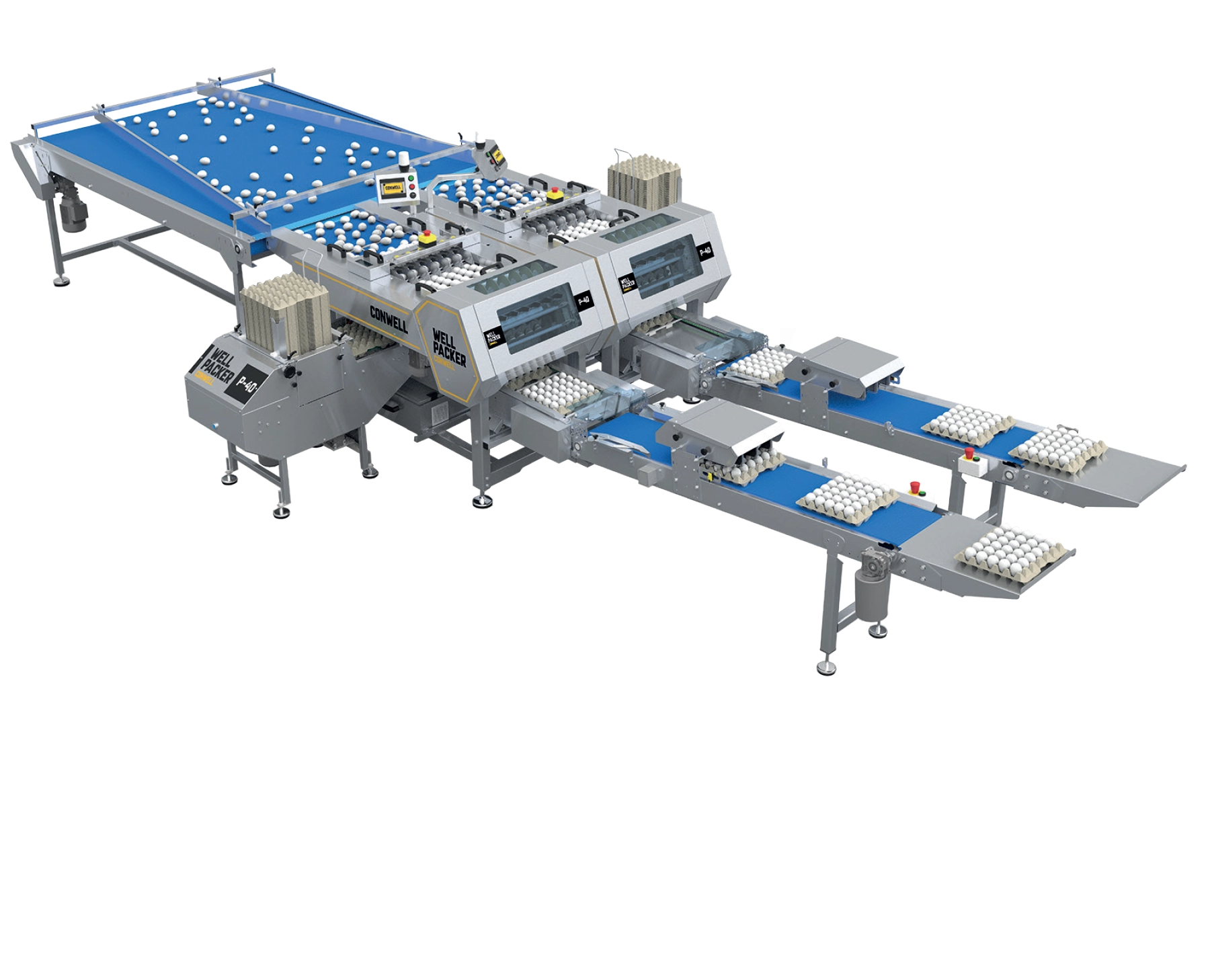

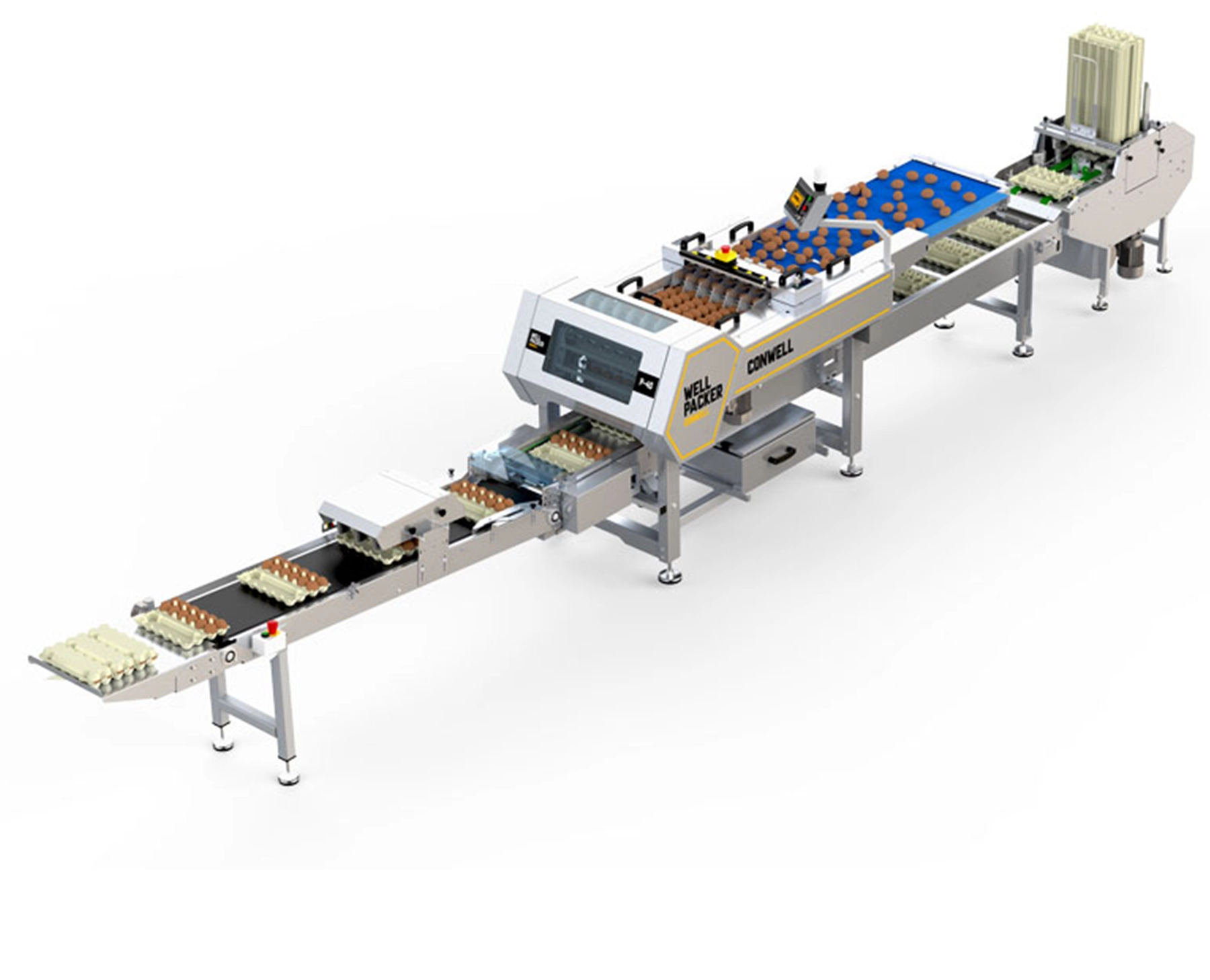

Up to 4 automatic packing machines can be connected.

Eggs are sorted into up to 7 different weight classes. The selected maximum of 4 grading groups can be automatically filled into trays.

In a system with 4 automatic packing machines, the groups with the lowest quantity and up to 3 separate groups are directed to manual trays for packaging.

Designed for single-head printer installation. All eggs are weighed and coded according to weight class or output line, ready for dispatch.

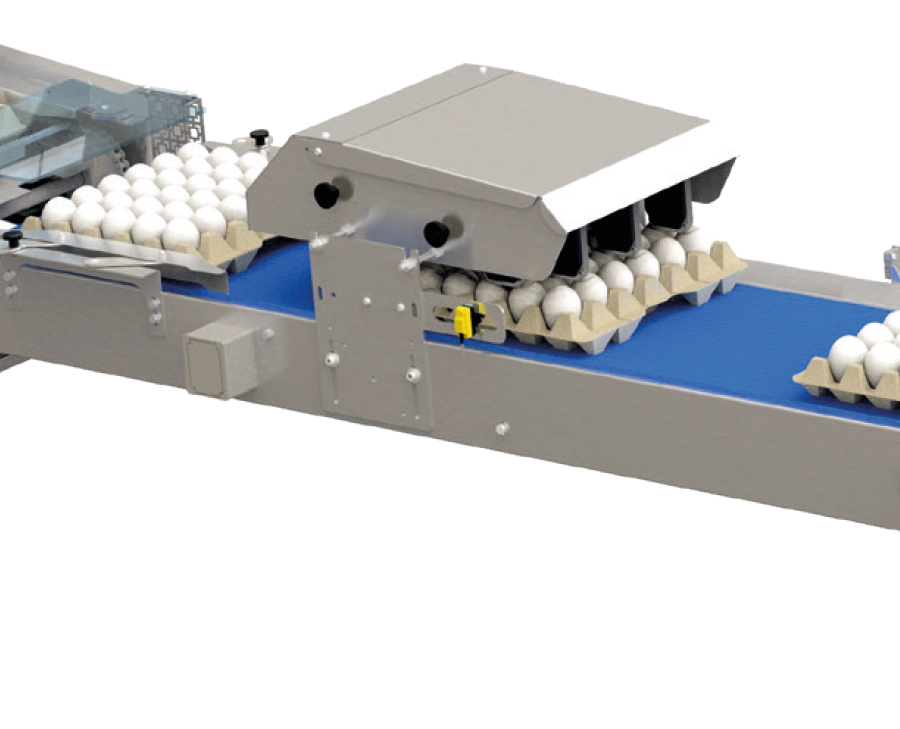

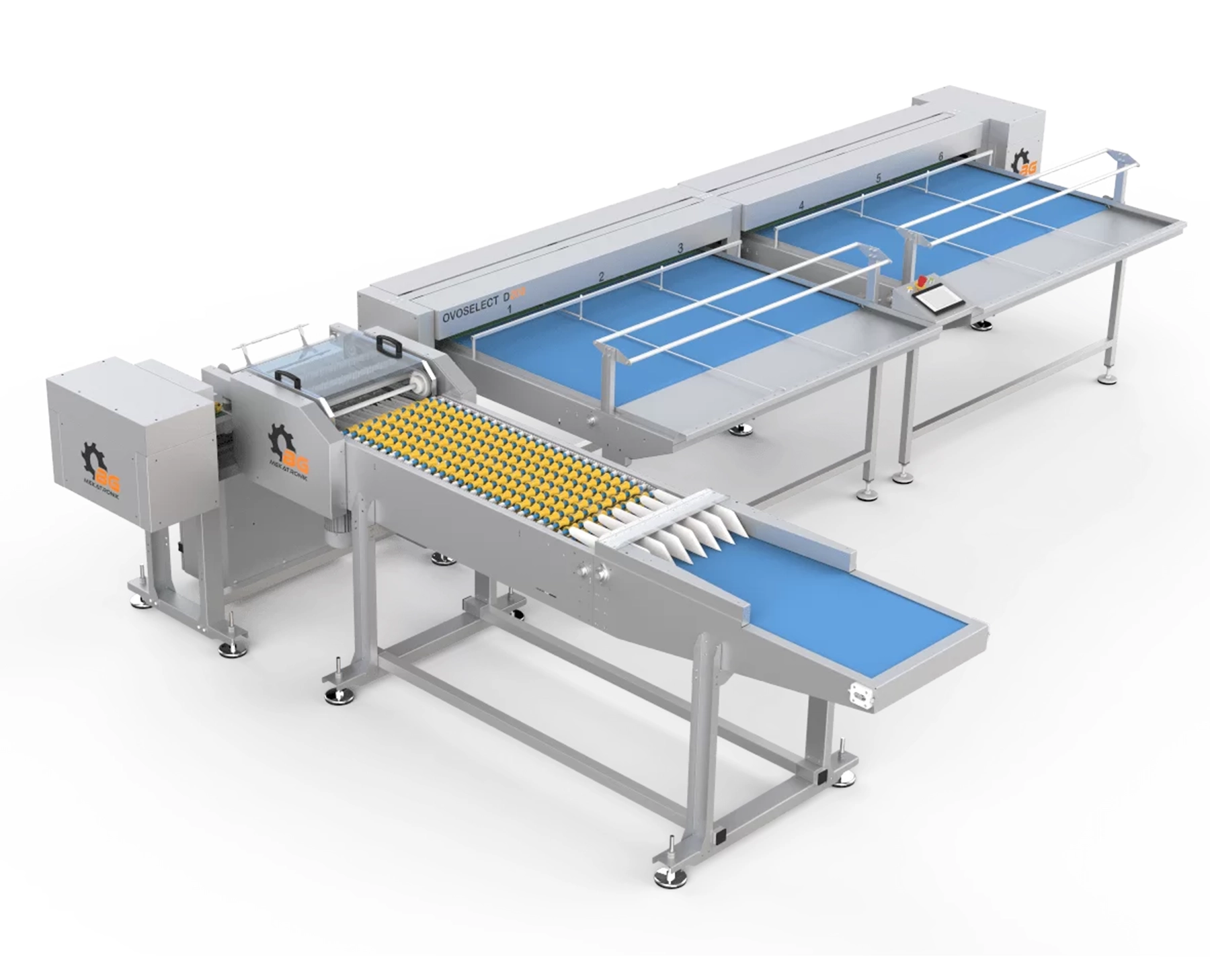

DX300 features a single-row speed and acceleration-controlled egg conveyor. Specially designed carriers ensure even the most delicate eggs are transported without pressure or breakage.

OvoSelect DX300 is made of stainless steel and washable.

7″ color LCD touchscreen provides easy visual operation.

DX300 includes 6 egg transport rollers.

OvoSelect DX300 – Key Features

- Modular design, removable parts

- Egg entry belts are easily detachable and cleanable

- Entirely stainless steel

- High-quality electronic weighing system

- Low maintenance cost

- Easy to use

- Fast and quality after-sales service

- Manual or automatic line options

- Broken egg inspection area, darkroom

- Daily analysis storage after grading

Printer Installation

Designed for mounting egg printing machines.

Egg Collection Table

1-3 manual collection tables can be installed in DX300 output lines. Eggs are transported to the operator via antibacterial modular belts. Empty trays are provided.

Easy Connection to Poultry Egg Line

DX300 feed belt allows egg input from three sides. Density detection prevents stacking and breaking during transfer.

Antibacterial and Cleanable Rollers

Egg rollers are made from antibacterial materials and are easy to clean.

Cracked Egg Inspection Area

Illuminated darkroom allows easy identification of cracked eggs.

Egg Conveyor and Carriers

Single-row speed and acceleration-controlled conveyor ensures delicate eggs are transported without damage.

Technical Specifications

| Capacity: | 30,000 eggs/hour |

| Input Lines: | 6 lines |

| Weighing System: | Electronic |

| Weighing Accuracy: | 0.1 g |

| Grading Classes: | 6 or 7 groups |

| Operation: | 7″ LCD touchscreen |

| Analysis: | Egg count and average weight |

| Power Consumption: | 2.0 kW + (4×1.2 kW) = 6.8 kWh, 380VAC (with 4 automatic collection) |

| Weight (Net/Gross): | 3,080 kg / 3,280 kg |

Professional Solutions for Egg Production from Start to Finish